News & Highlights

In the News

In the News

LLNL: Energy-efficient process delivers rare-earth element for magnets

Research Highlight

Research Highlight

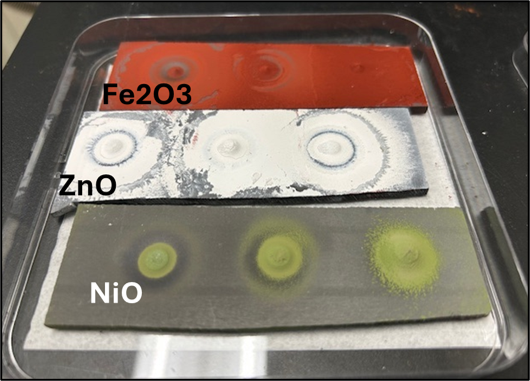

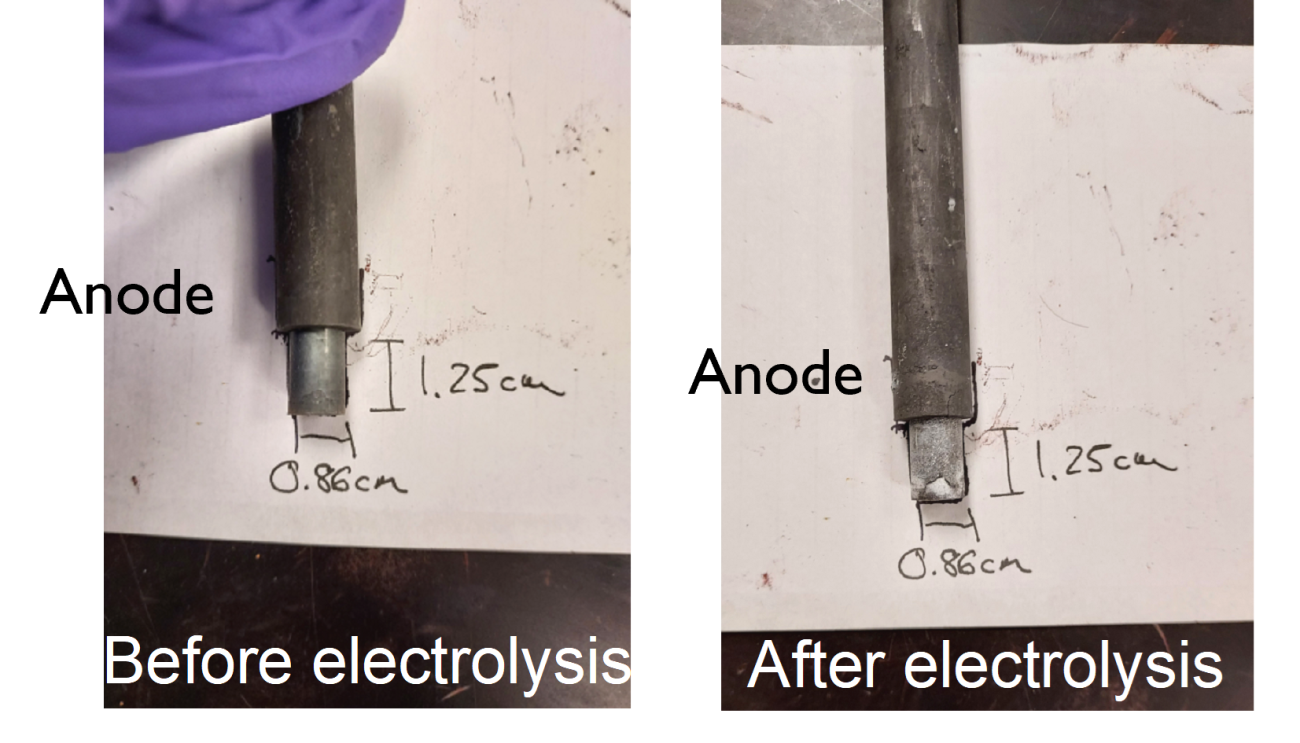

Cold-sprayed oxide anodes for Nd molten salt electrolysis

40 MGOe magnet using Nd electrowon from chloride molten salts

Research Highlight

Research Highlight

Dimensionally-stable anode for molten salt electrolysis of neodymium in chloride melts

First NdFeB magnet fabricated using Nd metal from CWRU’s sustainable electrowinning process

This project will develop a novel electrochemical reactor for ‘continuous’ production of neodymium metal from domestic ores. Continuous processing has the advantage of superior energy efficiency, reduced cost, improved control, and ease of process scalability. The electrochemical reactor will employ a molten salt electrolyte comprising chloride species instead of conventional oxyfluorides. This enables an environmentally-friendly process that is free of greenhouse gas emissions. The research team will design the electrochemical reactor, build and demonstrate its operation, and optimize a proprietary anode coating to function efficiently at the operating conditions needed for ‘continuous’ molten neodymium metal production. Complementary tasks will include materials characterization to confirm metal product purity, develop new methods for proprietary anode coating fabrication, and a collaboration within the Critical Materials Innovation Hub for Techno-Economic Analysis (TEA) and Life Cycle Assessment (LCA). Upon successful completion, this project will enable the deployment of a domestic rare-earth metal production process helping to safeguard the U.S. critical materials supply chain.