CMI researchers from Ames National Laboratory conducted the activity for this highlight

Innovation

Demonstration of commercial-purity Nd production via commercially competitive NdFeB magnet fabrication.

Achievement

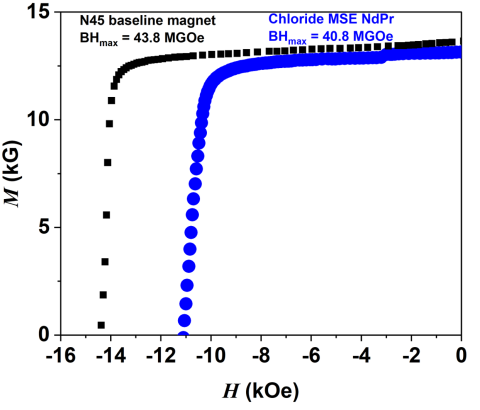

Electrolysis reactor with improved current distribution was designed, fabricated and operated, producing high-purity Nd metal at rates that are ~10X compared to SOTA. An NdFeB magnet with 40 MGOe energy product was successfully fabricated without the use of Dy, approaching the baseline N45 magnet. Next steps include process scale-up to reduce sample impurity variation, and better control of the magnet fabrication process.

Significance and Impact

Demonstration of NdFeB magnet (using Nd electrowon from chloride MSE) with properties close to commercial NdFeB.

Hub Goal Addressed

Energy-efficient rare earth metals production.