CMI researchers from Lawrence Livermore National Laboratory and Case Western Reserve University conducted the activity for this highlight

Innovation

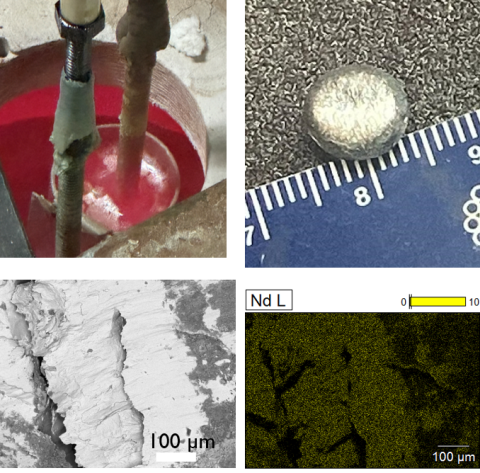

Chloride-based molten salt electrolysis for electrowinning of high purity liquid Nd.

Achievement

- Consistent production of gram level quantities of high purity Nd (~99.5 wt. %).

- Stable anodes are not consumed, enabling continuous operation.

- Galvanix Inc. (SBC in OH) is commercializing the process.

Significance and Impact

Greener, lower-cost approach than existing MSE approaches for Nd, enabling a domestic supply chain for NdFeB magnets. Continuous operation allows for both improved throughput and reduced post processing.

Hub Goal Addressed

Energy-efficient rare earth metals production.