CMI researchers from Case Western Reserve University conducted the activity for this highlight

Innovation

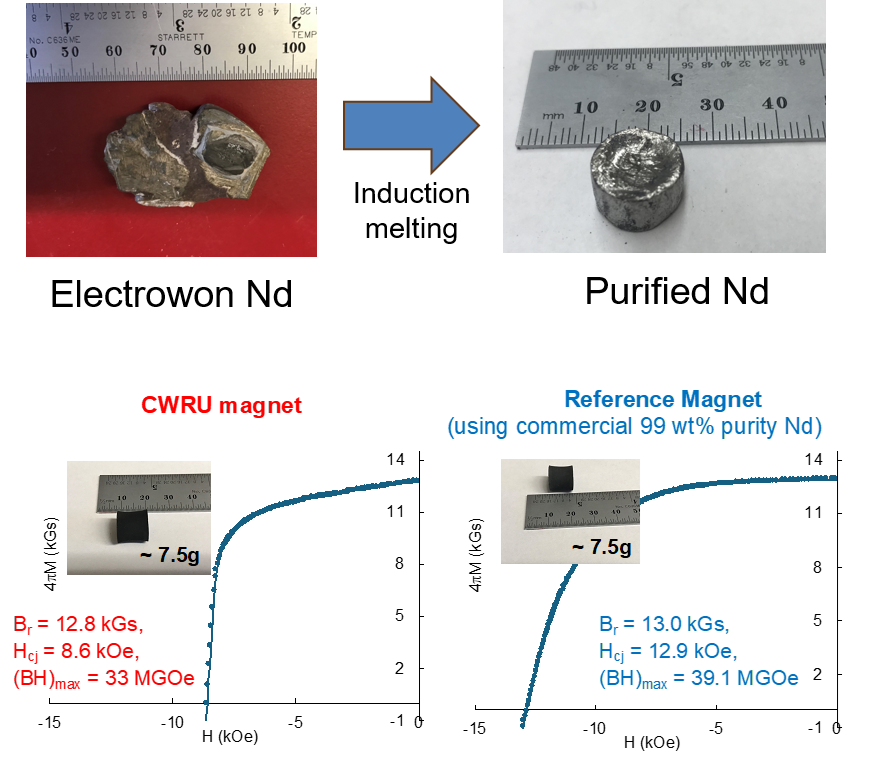

CMI researchers developed a novel chloride-based electrolysis process at Case Western Reserve University, and show that it can be used for sustainable, energy-efficient, domestic production of neodymium metal.

Achievement

The electrowon Nd was shipped to Ames National Laboratory for induction melting and NdFeB magnet fabrication. The magnet energy product compares well with magnets employing commercial purity Nd. Further process optimization is ongoing.

Significance and Impact

First demonstration of NdFeB magnet with reduced greenhouse gases. Demonstrate viable integration into domestic supply chain.

Hub Goal Addressed

Decarbonized rare earth metals production.