CMI researchers from Lawrence Livermore National Laboratory and Case Western Reserve University conducted the activity for this highlight

Innovation

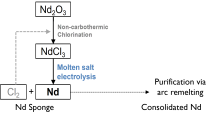

First fully sustainable Nd electrowinning process enabled by novel reactor designs and a dimensionally stable anode that reduces greenhouse gas emissions.

Achievement

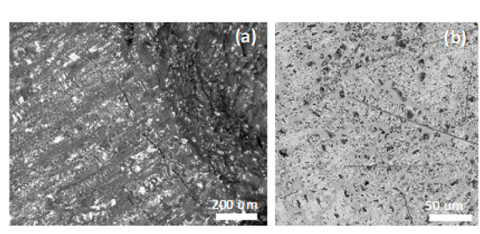

Arc-melting process enabled the production of Nd metal (95 atomic percent purity achieved) without Cl residue from electrowon Nd.

Significance and Impact

- Nd metal production at 2.3 kWh/kg energy consumption vs. 3.3 kWh/kg state-of-art, with corresponding GHG reduction.

- Eliminated Cl from deposit, increasing Nd purity to >95 at.% in large regions.

- Significantly reduced GWP as confirmed through LCA .

Hub Goal Addressed

Energy-efficient rare earth metals production.