This CMI-funded research was conducted at Idaho National Laboratory.

Achievement:

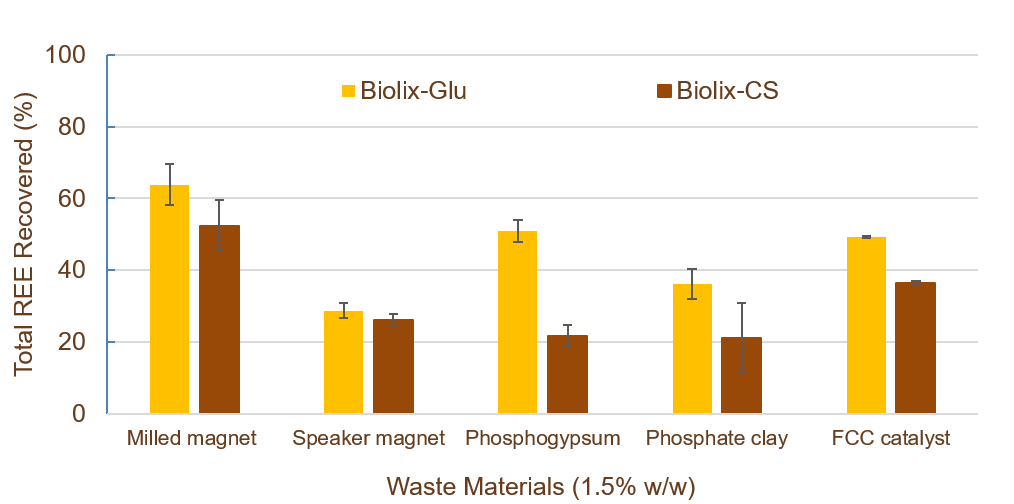

- Biologically generated lixiviant from corn stover was applied for rare earth element (REE) recovery from waste materials

- Highest recovery from the magnetic material that had been milled.

- The bioleaching process can be applied to fertilizer industry phosphate clay and phosphogypsum wastes

Significance and Impact:

Use of corn stover as a carbon source for biolixiviant production is comparable to using glucose, with respect to the bioleaching recovery of REE from some of the waste streams tested.

Details and Next Steps:

Improve bioleaching efficiency by engineering Gluconobacter oxydans for production of lower pH biolixiviant when grown on xylose and glucose mixtures as found in corn stover