News & Highlights

Momentum Technologies expands platform to support national supply chain for rare earth elements

Research Highlight

Research Highlight

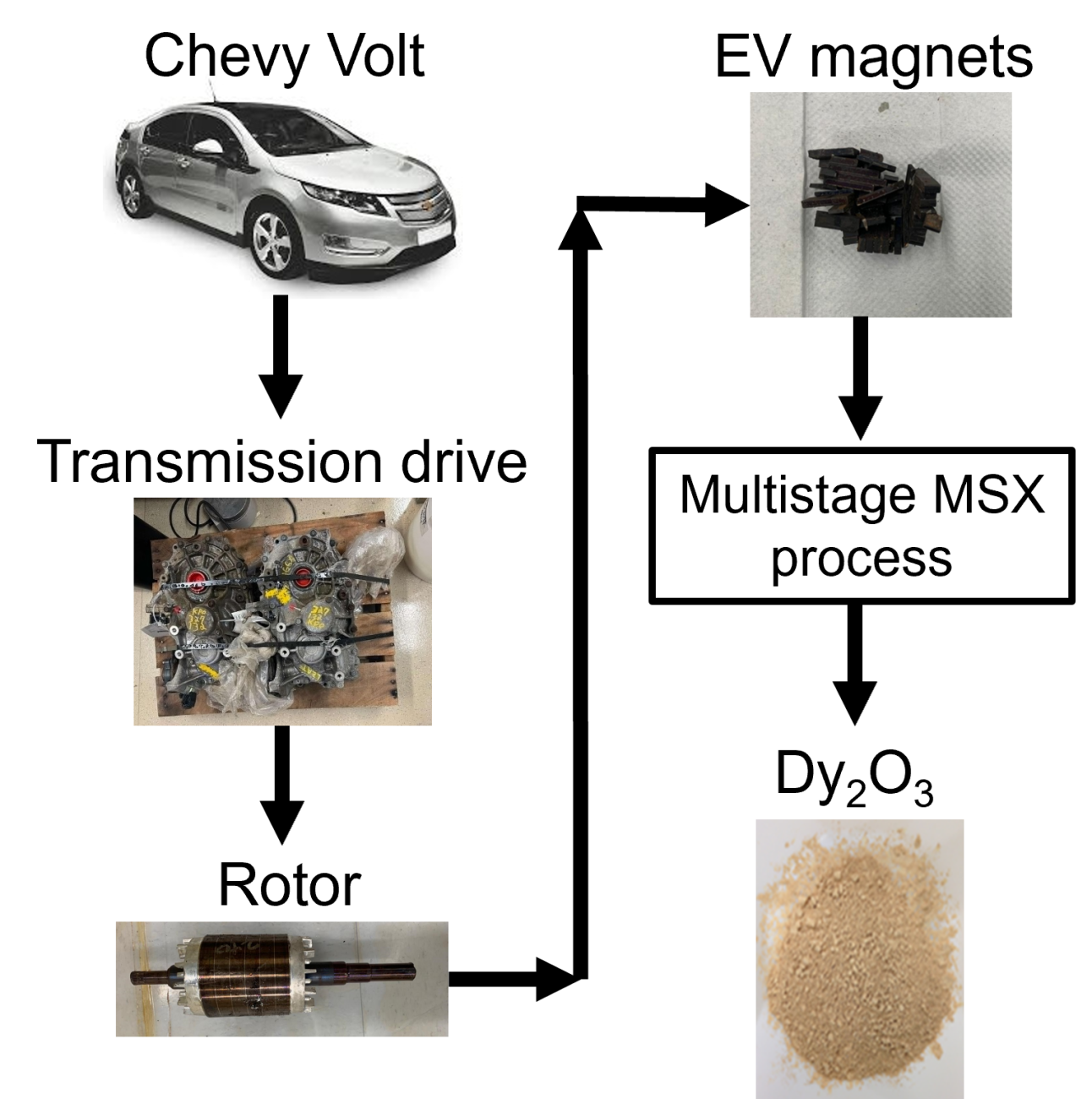

Highly selective MSX process recovers heavy rare earth elements

WVLT: Breaking Ground: Saved from the scrapyard, a big Tennessee economic boost

Dallas Innovates: Momentum Technologies opens new HQ and R&D Lab in North Texas

Research Highlight

Research Highlight

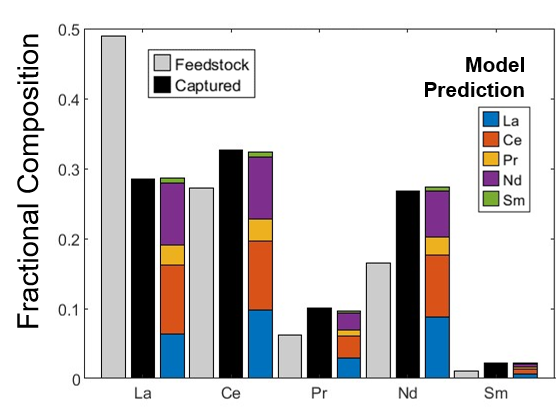

Modeling REE binding of lanmodulin to guide separation optimization

In this project, novel Membrane Solvent Extraction (MSX) technologies will be evaluated based on the previous experience and in-depth understanding of MSX for rare earth element (REE) extraction from various feedstocks to recover high purity heavy rare earth directly from intra-lanthanide separations. The effect of process conditions such as type of extractant, different extractants (cationic and neutral extractants), type of extractant diluent, different feedstocks, feed solution concentration, feed/strip pH, extractant composition, and feed/strip residence time will be investigated to achieve high extraction rates and separation factors for dysprosium (Dy) over other metal constituents in respective processes. Preliminary Techno-Economic Analysis (TEA) will be performed to assess the cost-effective of the MSX process.