News & Highlights

Research Highlight

Research Highlight

Two Enhancing and Diversifying Supply projects available for licensing

Research Highlight

Research Highlight

CMI offers tutorials during technical meeting to encourage discussion among CMI Team members

Research Highlight

Research Highlight

Diversifying lithium supply brines to hard-rock minerals: vacuum-induced thermal extraction of Li from α-spodumene (VITELiS)

Research Highlight

Research Highlight

Mechanochemical processing of lithium mudstone for facile water extraction

Research Highlight

Research Highlight

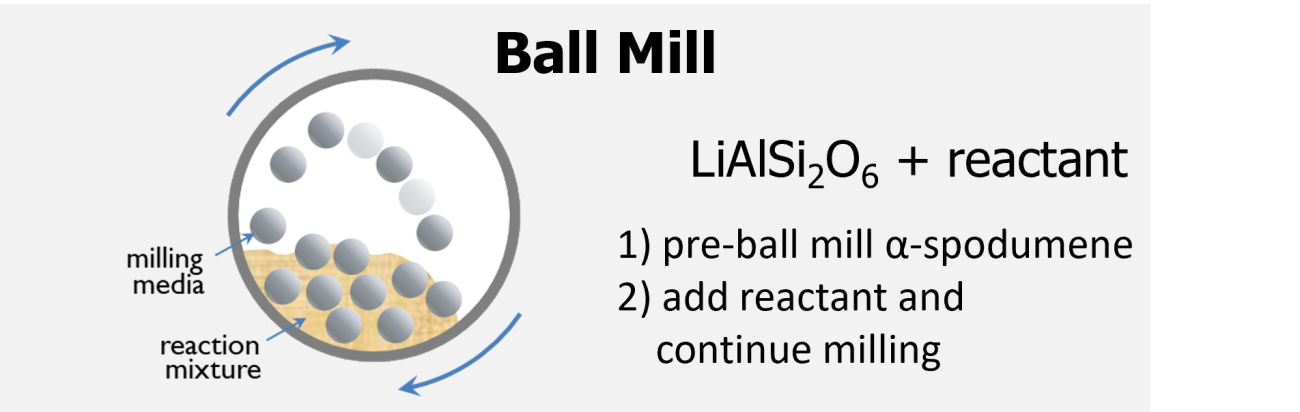

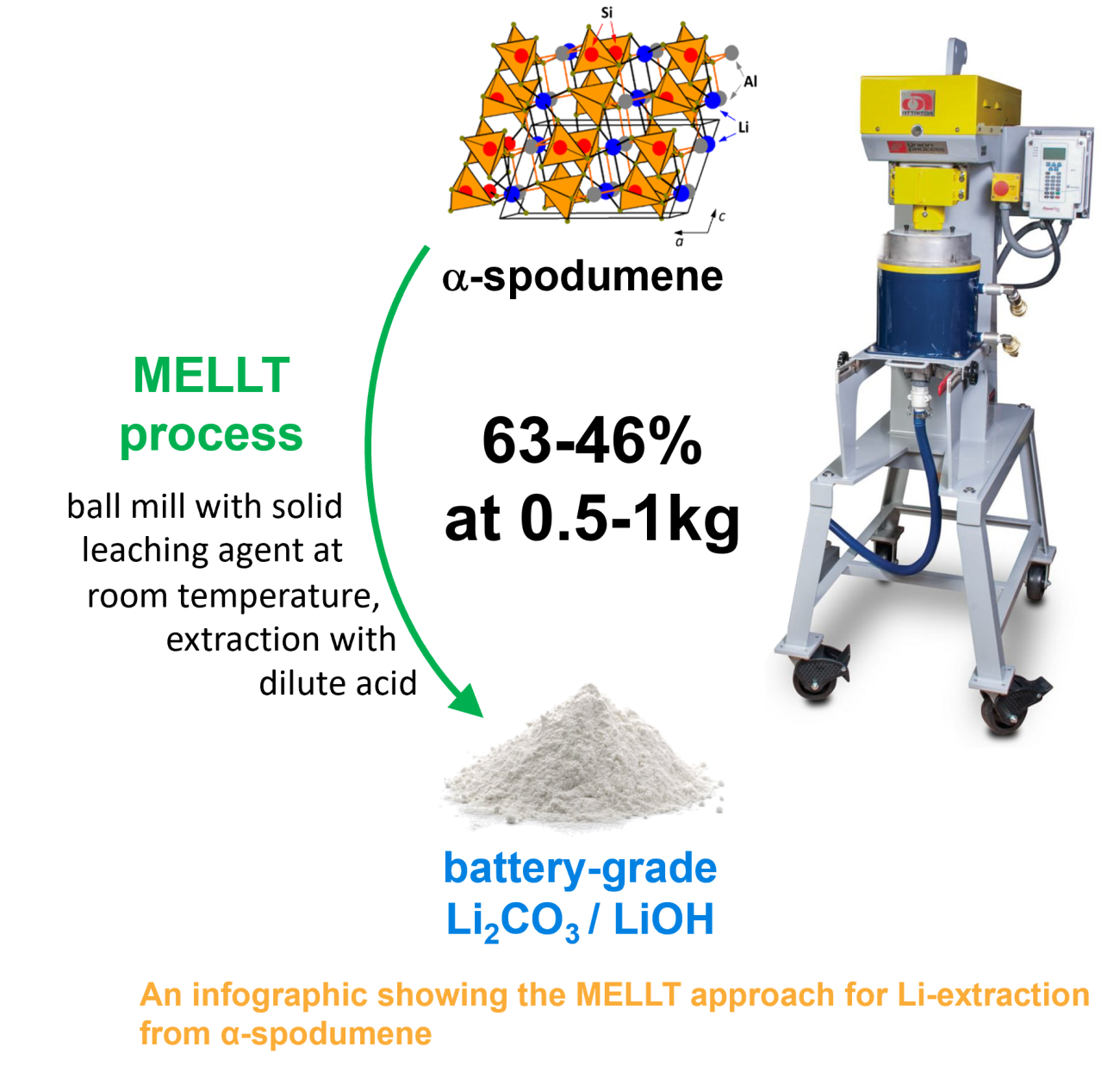

Diversifying lithium supply from brines to hard-rock minerals: mechanochemical extraction of lithium at low temperature (MELLT) from α-spodumenes

In the United States, brines are the primary source for lithium extraction. However, their long lead times and low lithium extraction yields limit their ability to meet the recent surge in demand. To ensure supply chain sustainability, it is crucial that new hard rock assets, namely spodumenes, are utilized. The major barrier to the implementation of lithium extraction from hard-rock minerals is the significant energy consumption and hazardous waste generation associated with the current industrial methods. To address these challenges, this project will employ mechanochemical reaction that bypasses the most energy demanding step while simultaneously reducing the overall chemical waste.

Ames National Laboratory produced this video about "Diversifying Lithium Supply from Brines to Hard-Rock Minerals," where CMI project lead Ihor Hlova describes advantages of a method of mechanochemical extraction of lithium at low temperature (MELLT) from α-Spodumenes. This CMI technology was a finalist in the 2024 R&D 100 Awards program.