CMI researchers from Ames National Laboratory and an industry partner conducted the activity for this highlight

Innovation

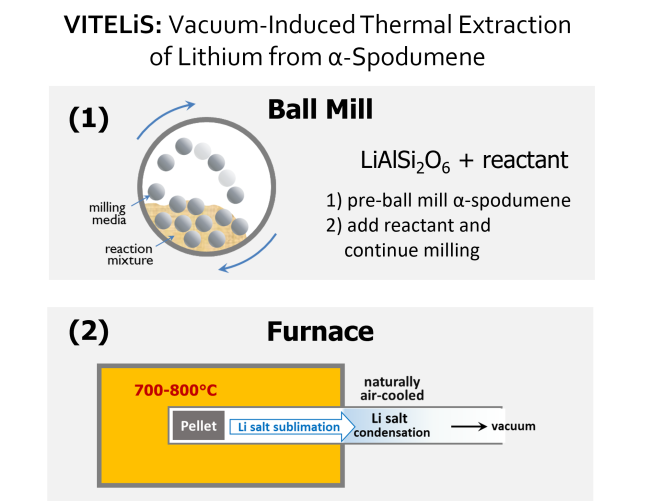

VITELiS (Vacuum-Induced Thermal Extraction of Lithium from α-Spodumene) aims to unlock >85% of lithium available in domestic hard-rock ore, diversifying the lithium supply

Achievement

Developed a novel method that reduces mechanical energy input compared to the previously developed MELLT (Mechanochemical Extraction of Lithium at Low Temperature) process. A patent application has been submitted for VITELiS (ISURF #05819).

Significance and Impact

- Reducing processing time from more than 100 times (64h to 30 min), and temperature from 1100°C to 800°C

- Technology operates entirely without harsh acids, bases, or water

- Direct one-step extraction

Hub Target Addressed

Recovery or purification processes to expand U.S. lithium production; highly selective extraction and separations; minimizing hazardous chemical use and waste generation