CMI researchers at CMI Team members Ames Laboratory and Oak Ridge National Laboratory collaborated for this highlight

Achievement

Additively manufactured (AM) and surface-protective-resin coated bonded magnets meet the industrial stability criterion at 175 °C with a flux-loss of only 2.35% after 1000 hours aging.

Significance and impact

This study demonstrates that AM fabricated bonded magnets with reduced manufacturing waste may offset some critical rare earth element demand through targeted use in high-efficiency motors.

Next steps

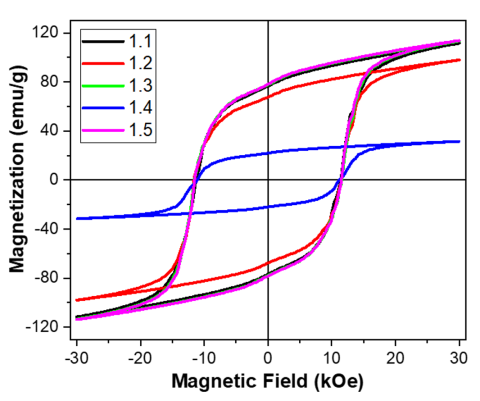

- AM printed polyphenylene sulfide (PPS) magnets are strong compared to nylon counterparts; low eddy current loss; corrosion resistant; high energy product isotropic magnets

- PPS binders can be used for higher temperature applications

- Manuscript published in Materials journal

- Produce mechanical and thermally stable anisotropic magnets