CMI scientists at Idaho National Laboratory contributed to this research.

Achievement

The results of electrochemical leach process (EC Leach) developed by CMI project 3.1.11 were formulated into a paper recently accepted (April 17, 2020) by the journal Resources, Conservation & Recycling.

Significance and impact

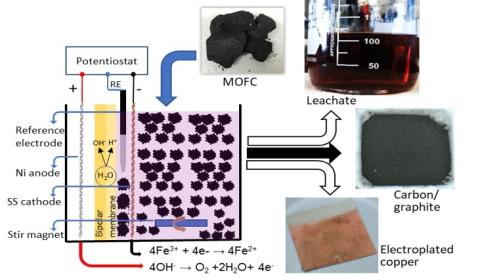

- Produces a concentrated metal leachate (high pulp density)

- Chemical use greatly reduced with mediated reductant

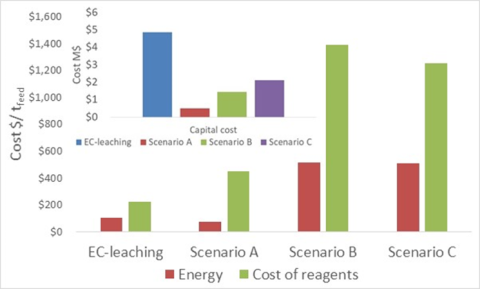

- Process has a lower OPEX but greater CAPEX compared to purely chemical processes

- Other co-products are graphite and copper

Details and next steps

- Incorporate results into a comprehensive model to assess economics

- Continue development of metal recovery methods

- Revise cell design for larger feed (60 g/day currently)