CMI scientists at Oak Ridge National Laboratory conducted this research.

Achievement

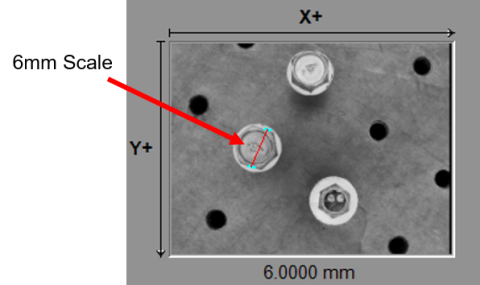

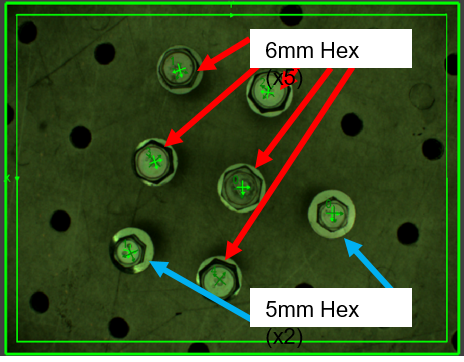

ORNL has demonstrated the ability to determine the size and type of several unknown fasteners from automobile drive trains using an image processing system.

Significance and impact

An array of unknown fastener size and type was determined in approximately 154ms by programming a commercial machine vision system. The fasteners identified are commonly used for interior and exterior fastening applications on electric machines and lithium ion battery stacks. This system enables rapid fastener identification and is repeatable with high accuracy. Trials ‘n’ =100 resulted in 100% pass rate.

Details and next steps

- ORNL designed an image processing process to extract size, type and location of hex type fasteners with high accuracy and repeatability.

- Next, perform multi-fastener recognition: Classify multiple types of fasteners (e.g. torx, hex, Philips, flat, security torx, etc.).