This research was performed by CMI scientists at Idaho National Laboratory with CMI Team member Retriev.

Achievement

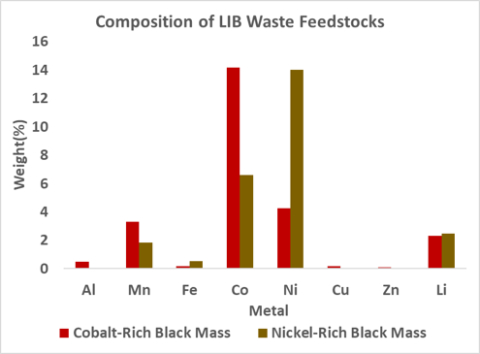

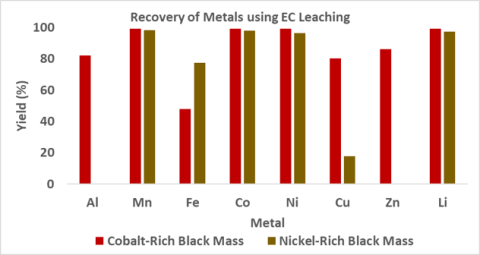

- We have demonstrated that our EC leaching process efficiently leaches feedstocks with variable compositions.

Significance and impact

This demonstrates EC leaching is robust for various waste feedstocks including a cobalt rich and nickel-rich feedstock.

- Further proof to justify effectiveness of EC leaching method

- With demonstrated robustness, we can move forward to optimize process for time and iron sulfate addition

Details and next steps

- Produce pure metals for Y7 milestones

- Test recovered graphite in new LIB batteries

- Evaluate AZR feedstock and demonstrate recovery pathway