CMI researchers from the Ames National Laboratory conducted the activity for this highlight

Innovation

Direct conversion of Nd2O3 into high performance Nd2Fe14B permanent magnet material through a one-step calciothermic reduction.

Achievement

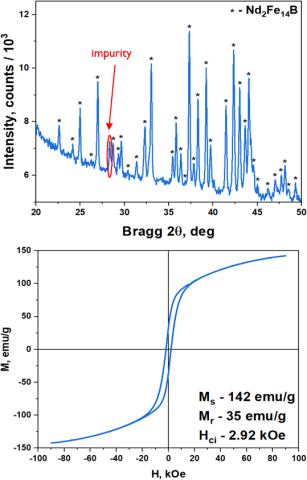

Produced a Nd2Fe14B powder with at least 92% phase purity (by x-ray diffraction) and high magnetization (~85% theoretical).

Significance and Impact

One-step calciothermic procedure circumvents the currently employed, environmentally unfriendly neodymium metallization process through the direct production of Nd2Fe14B permanent magnet powder from Nd2O3 and Fe, paving a pathway for domestic permanent magnet production.

Hub Target Addressed

Reducing the chemical, material, and energy intensity in permanent magnet materials processing and thereby increasing manufacturing efficiency.