CMI researchers at Ames National Laboratory conducted the research for this highlight

Innovation

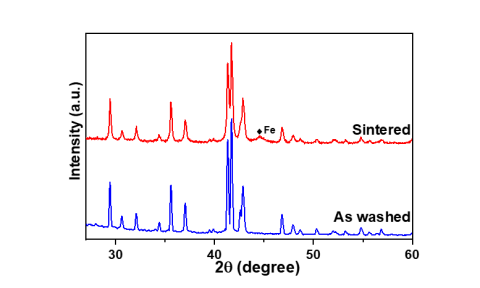

Conversion of Sm2O3 into Sm2Fe17 phase via reduction-diffusion approach produces nearly oxygen-free, sinterable Sm2Fe17N3 powders.

Achievement

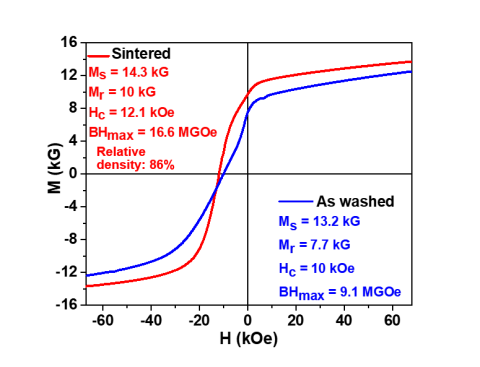

Synthesis of Sm2Fe17 powders directly from Sm2O3 leads to a magnet that after nitrogenation and sintering at 420°C reaches a relative density of 86% and shows substantially improved hard-magnetic properties, with energy product, BHmax=16.6 MGOe.

Significance and Impact

- Criticality and cost: the material is mostly Fe (~74% wt.%) and it contains non-critical rare earth, Sm, as well as other earth-abundant constituents.

- When fully developed, thermally-stable Sm2Fe17N3–based materials are expected to become competitive with Nd2Fe14B-based magnets.

Hub Goal Addressed

Reducing critical rare-earth content in strong permanent magnets.