CMI researchers at Idaho National Laboratory conducted the research for this highlight

Innovation

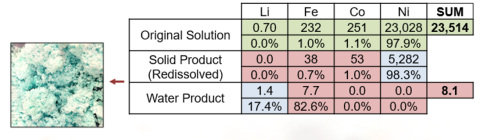

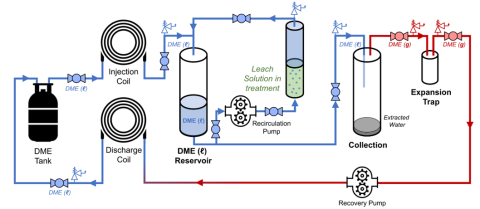

Dimethyl ether (DME) used to remove water and crystallize solids from a Ni-rich recycling stream derived from electrochemical leaching of lithium-ion battery (LIB) black mass.

Achievement

Production of high purity and low-moisture solid (metal content 98.3% nickel) and highly purified water.

Significance and Impact

Opportunity to achieved closed loop water reuse during critical materials processing.

Hub Target Addressed

Advancing environmentally friendly and efficient recovery of critical materials from end‐of‐life energy storage devices