CMI researchers at Idaho National Laboratory conducted the research for this highlight

Innovation

Two mixed oxide precursors (Nd2O3+Fe2O3 and Sm2O3+CoO) show promise for conversion to NdFe and SmCo alloys by a one-step electrochemical process.

Achievement

- A chemical purity >90% for the NdFe alloy was obtained.

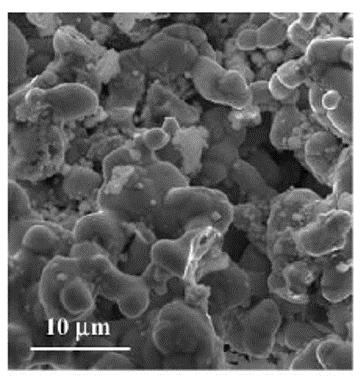

- Sintering of the oxide powder, prior to reduction, proved an essential unit operation vis-à-vis non-sintered (mixed) powders.

Significance and Impact

Cost-effective preparation of rare earth-transition metal alloys.

Hub Target Addressed

Development of a green, inexpensive manufacturing technique for the production of metallic rare-earth alloys.