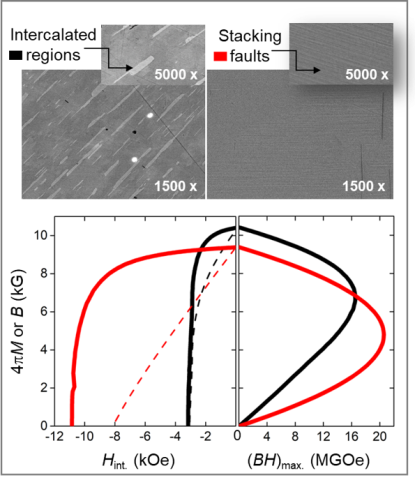

Lower figure: magnetic hysteresis loops. Record coercivity of ~10.6 kOe is achieved in the sample with uniform, anisotropic stacking faults. This yields (BH)max > 20 MGOe.

CMI researchers at Ames National Laboratory conducted the research for this highlight

Innovation

Novel cerium-based magnets for U.S. national needs.

Achievement:

- Development of heat treatment (HT) procedure, which facilitates formation of 2:7-type stacking faults (instead of intercalated regions), strictly anisotropic and evenly dispersed within the matrix material.

- Microstructure yields development of record ~10.6 kOe (BH)max = 20.4 MGOe of coercivity and energy product, respectively.

Significance and Impact

Magnet is viable lower-cost competitor to SmCo magnets at lower Co content (43 wt.% vs. 53+%) using earth-abundant, inexpensive, industrial grade Cerium.

Hub Goal Addressed

Win industry adoption of three technologies related to materials substitution for rare earth magnet materials.