CMI researchers at Ames Laboratory, Lawrence Livermore National Laboratory, University of Tennessee, Knoxville and Eck Industries conducted the activity for this highlight

Innovation

Metal 3D printing of Aluminum-Rare Earth Element (Al-REE) alloy forms internal extremely degradation-resistant nanostructure.

Achievement

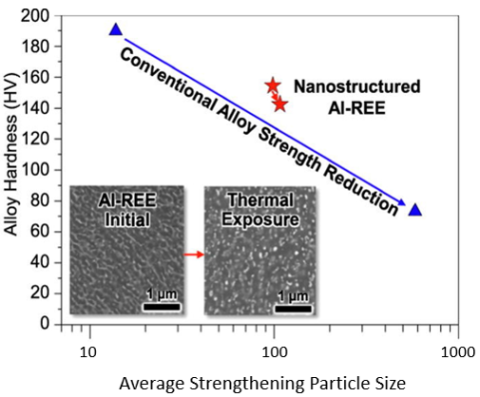

- Nanoscale particles form during 3D printing and resist coarsening during thermal exposure

- Compares well to established high performance Al alloys.

- Differences in particle connectivity and size can be controlled to alter mechanical behavior in the alloy.

Significance and Impact

Enhanced thermal performance makes these Al-REE alloys appropriate for high temperature applications previously impossible for Al, thereby helping increase demand for underutilized Ce.

Hub Target Addressed

Diversify supply of REE by increasing demand for C