CMI researchers at Lawrence Livermore National Laboratory, University of Tennessee-Knoxville and Ames Laboratory conducted the research for this highlight

Achievement

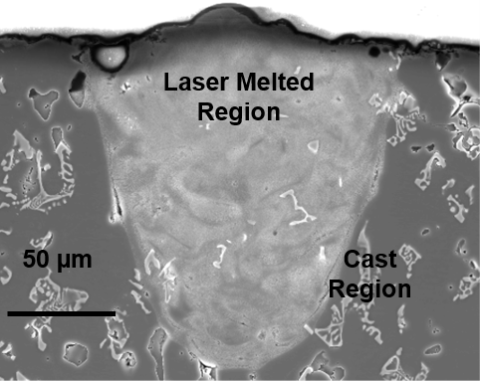

Demonstrates that selective laser melting—a type of additive manufacturing (AM)—can create Al-Ce alloys with superior mechanical properties not achievable with conventional processing.

Significance and impact

- Shows how nanostructures and enhanced mechanical properties can be achieved using additive manufacturing techniques.

- AM Alloys can enable green technologies such as improved heat exchangers and lightweight structural components and will expand the use of cerium, stabilizing the domestic rare earth supply.

Next steps

Further development of AM-specific Al-Ce alloys.