CMI researchers at Idaho National Laboratory conducted the research for this highlight

Achievement

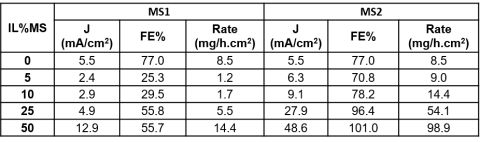

We have electrodeposited Dy metal and enhanced performance metrics by upgrading the ionic liquid (IL) with molecular solvents (MS).

Significance and impact

- Industrial production of Dy metal is achieved with molten salts and temperatures >900°C.

- Low temperature electrochemical deposition of Dy is desirable from an energetic, safety and environmental standpoint.

- In the ionic liquid process, no heat is applied. Instead, MS addition increased metal loading and improved mass transport (lower viscosity), while preserving product quality.

- In this system, Dy electrodeposition could operate at rates approaching 0.1g/h.cm2.

Details and next steps

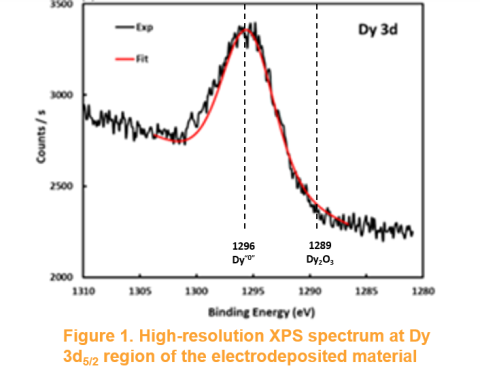

- Further XPS analysis is needed to confirm the oxidation state of electrodeposited Dy and corresponding metrics.

- Influence of anodic products on the oxidation state and/or performance metrics will be investigated.

- Techno-economical analysis is being updated.