CMI researchers at Ames Laboratory, Iowa State University and Purdue University conducted the research for this highlight

Achievement

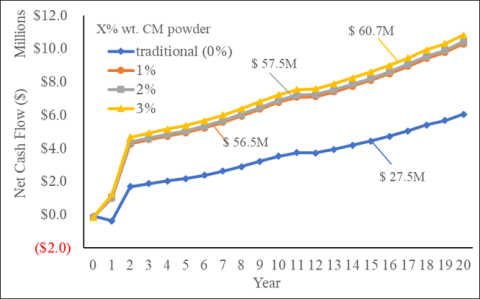

Techno-economic assessment of a new method for samarium-cobalt magnet processing indicates significantly improved profitability compared to the traditional approach.

Significance and impact

Increasing the mechanical strength of SmCo magnets by incorporating cryomilled (CM) powders during processing results in a lower defect rate, while maintaining compatibility with existing manufacturing methods. The reduced production costs provide a substantial competitive advantage.

Details and next steps

- The lower failure rate ensures profitability when the SmCo selling price is =$90/kg; the traditional method requires $123.5/kg.

- Design of Experiments will be applied for further improvement of economic performance.