CMI researchers at Ames Laboratory and Lawrence Livermore National Laboratory conducted the research for this highlight

Achievement

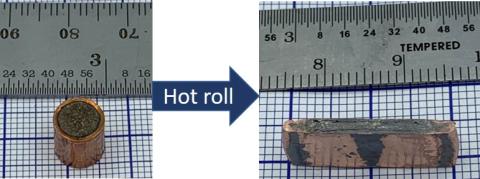

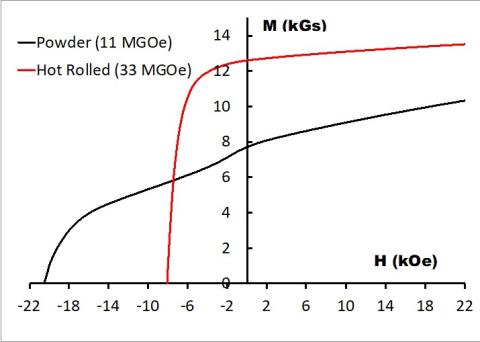

A new process for fabrication of small Nd-Fe-B magnets via hot rolling of powder in Cu-tubes is demonstrated. Large energy product of 33 MGOe was obtained with potential to exceed 40 MGOe.

Significance and impact

Manufacturing method allows making magnets of small dimensions. Novel process simplifies processing steps and reduces cost. Innovative use of deformable copper die enhances corrosion resistance and magnetic properties. Near-net-shape cross-section reduces waste of rare earth associated with machining.

Next steps

- Optimize processing parameters for higher magnet performance

- Scale-up for semi-continuous process

M-H loops of the processed thin magnet (in plane).