CMI researchers from FIPR Institute and Oak Ridge National Laboratory conducted the research for this highlight.

Achievement

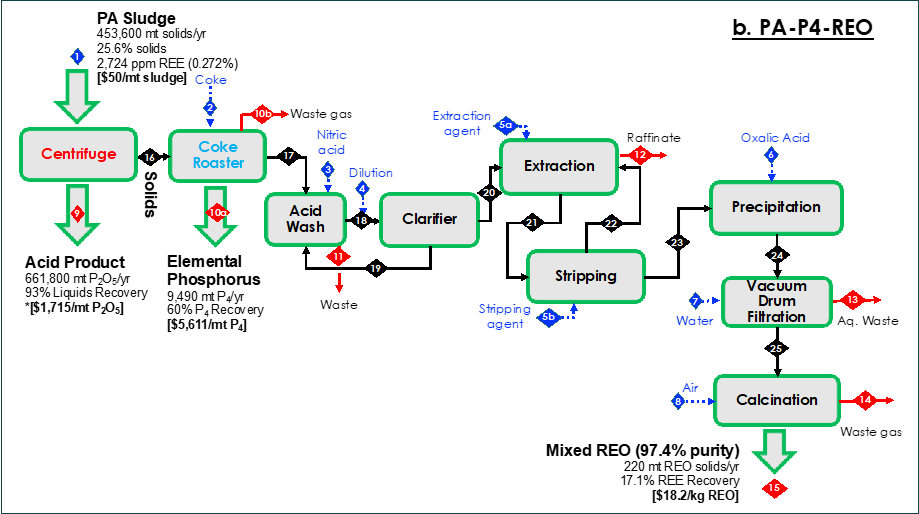

- Invented a process for recovery of P from sludge thus improving economics of REE recovery.

- Accomplished over 97% REE leaching recovery by thermal cracking.

- Developed two processing flowsheets for REE production from sludge with promising TEA and a commercialization plan.

Significance and Impact

- Three patented processes having broad implications to REE recovery from unconventional resources.

- A large portion of US demand for Y, Nd, Dy and Gd could be met if commercialization plan executed.

Hub Goal Addressed

Diversify and expand the supply of materials in the appropriate quantities needed for the clean energy transition.