CMI scientists at Lawrence Livermore National Laboratory led this research.

Achievement:

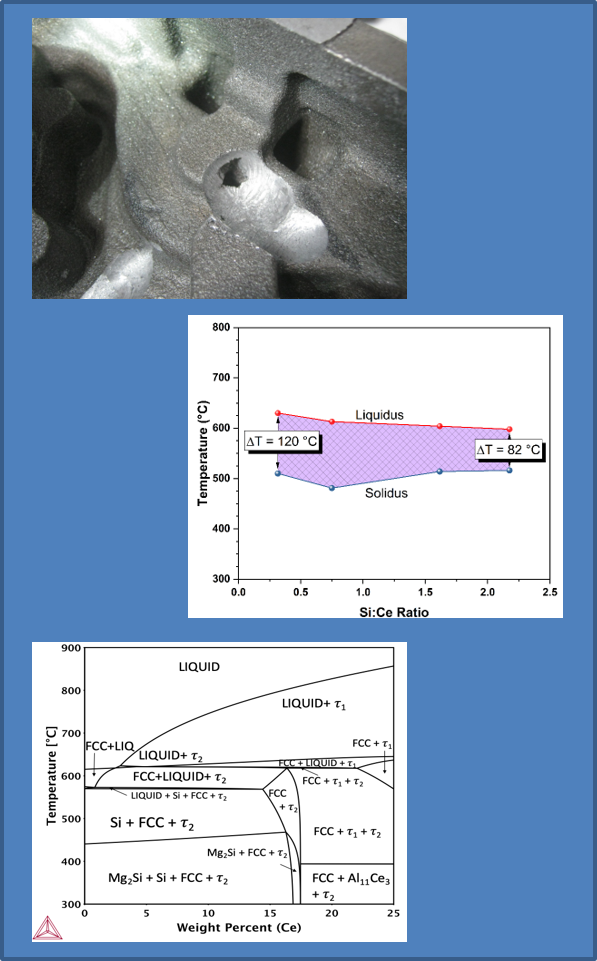

An Al-3.5Ce-0.4Mg-7Si alloy with improved casting and mechanical properties was developed with CALPHAD

Significance and Impact:

- Collaboration with Eck Industries and ORNL resulted in a new alloy composition

- Freezing ranges were computationally optimized to alloy for Additive Manufacturing (AM) conditions

- An ROI and publication is underway

Details and Next Steps:

- Established a feedback loop between the partnership

- Determined composition ranges by empirical relationships

- Performed casting experiments

- Thermodynamic calculations aided in optimizing freezing ranges for Ce modified A-356 alloys

- Additional Ce-modified Al alloy compositions are to be defined and included in a non-provisional patent filing