CMI researchers from Ames National Laboratory conducted the activity for this highlight

Innovation

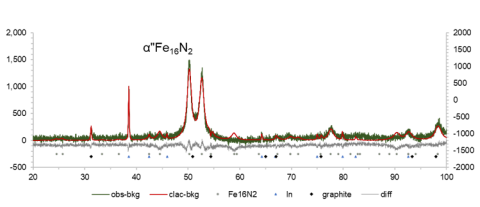

Demonstrated Spark Plasma Sintering (SPS) of α”-Fe16N2 without decomposition of the magnetic phase.

Achievement

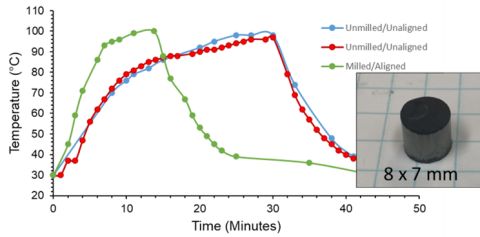

Demonstrated that SPS can be used to compact α”-Fe16N2 powders and that the behavior of the compaction changes with agglomerate size (as received vs low energy ball milling). The density of the part is enhanced using ~15% of a low temperature sintering aid.

Significance and Impact

- The α”-Fe16N2 is a truly critical element free magnetic compound.

- The challenge is to form the nanoscale compound into a dense monolithic part without degrading the magnetic phase.

Hub Targets Addressed

- Developing critical material free Iron Nitride based magnets.

- Accelerated magnet discovery and maturation.