CMI researchers at Idaho National Laboratory conducted the research for this highlight

Innovation

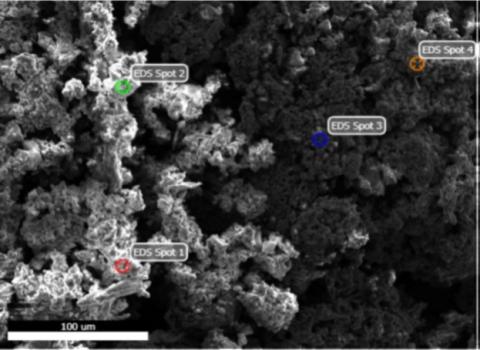

A powder metallurgical process was developed to prepare mechanically robust oxide precursor materials for conversion to constituent alloys.

Achievements

- Optimized conditions were established to prepare defect-free sintered bodies.

- The sintering temperature was determined to achieve twin properties: adequate mechanical strength and internal porosity.

- Sintered oxide bodies could be wetted fully upon immersion in a molten salt pool.

Significance and Impact

Preparation of cost-effective precursor materials.

Hub Goal Addressed

Creating a domestic source of rare earth magnet alloys.