CMI researchers from Purdue University conducted the activity for this highlight

Innovation

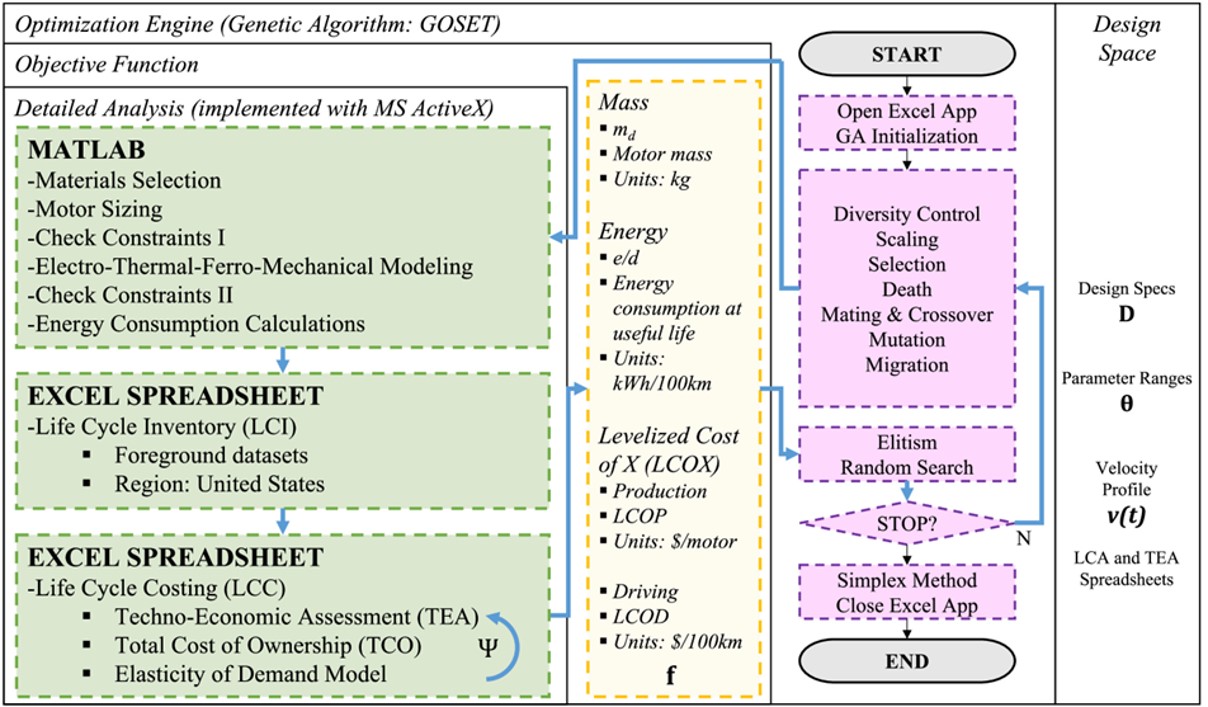

Use genetic algorithm to optimize traction motor design of 2019 Nissan Leaf S in terms of material selection, motor dimensions and other parameters. Considered four objectives tied to economic and environmental performance: motor mass, energy consumption, and levelized costs of production and driving.

Achievement

- NdFeB-based motors are ~40% less expensive than SmCo-based motors.

- Improving energy performance tends to increase production costs and decrease driving costs.

- NdFeB-based motors impact environment less than SmCo motors.

Significance and Impact

Decision-making framework can be adapted to other products.

Hub Target Addressed

Assessing economic, environmental, and social acceptance impacts.