CMI researchers at Ames Laboratory conducted the research for this highlight

Achievement

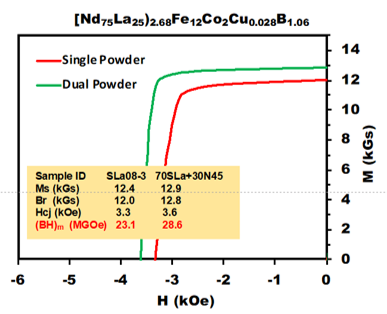

Validated a new magnet fabrication method [1] that produced 29 MG-Oe energy product in (Nd0.75La0.25)2Fe12Co2B composition, a significant increase from previous values.

Significance and impact

Result shows viability of simultaneous La and Co substitutions into Nd2Fe14B for a permanent magnet. Magnet made of a mixture of La-Fe-B and Nd-Fe-B powders (dual powder) exhibits larger coercivity and magnetization than the one made of pre-alloyed (La-Nd)-Fe-B powder. Powder size, mixing and compositions all play a role. This finding opens a new pathway to reduce the use of critical elements.

Next steps

- Optimize processing parameters for higher magnet performance

- Explore Nd-lean compositions