CMI researchers at Ames National Laboratory and Idaho National Laboratory conducted the research for this highlight, along with researchers at Massachusetts Institute of Technology and the National Alliance for Water Innovation (NAWI)

Innovation

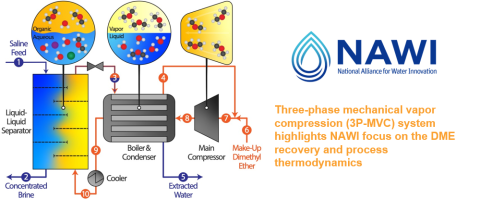

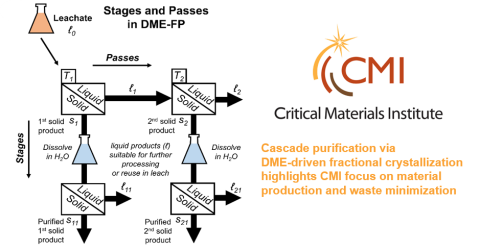

A pair of interrelated dimethyl ether (DME) driven separations that produce solids from aqueous solutions.

Achievement

Synergistic support to solve cross-cutting solid-liquid equilibrium (SLE) challenges in mineral separations, material production, water softening, and aqueous residuals minimization.

Significance and Impact

- CMI: New generalizable hydrometallurgical separation and waste treatment.

- NAWI: Cost effective zero-liquid discharge (ZLD) desalination for residual management.

Hub Target Addressed

Advancing next-generation atom- and energy-efficient separations for multiple applications.