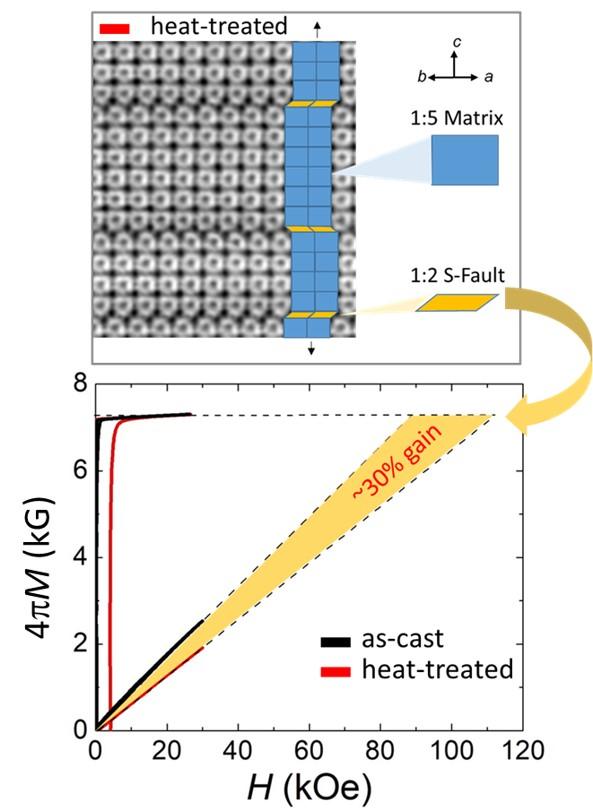

Lower: Easy and hard axes magnetization from the same material as-cast and heat-treated showing the anisotropy gain (in yellow) that corresponds to the appearance of stacking faults.

CMI researchers at Ames Laboratory conducted the activity for this highlight

Innovation

Economical Ce-based permanent magnets with readily available coercivity.

Achievement

- Structurally induced magnetic anisotropy gain up to 30% caused by strain.

- Because of reduced low-temperature solubility the material becomes faulted, i.e., 1:2 S-Faults (see Figure) generate strain and increases magnetic hardness

Significance and impact

- Anisotropy gain is solely structural, without change of alloy composition

- The structural transformation will be used for displacement of critical Co, e.g., by increasing magnetic hardness of structurally similar weakly anisotropic Fe-systems

Hub target addressed

Win industry adoption of three technologies related to materials substitution for rare earth magnet materials.

O. Palasyuk, M. Onyszczak, T-H. Kim, L. Zhou, M. J. Kramer, S. L. Bud’ko, P. C. Canfield, A. Palasyuk. “Structural and magnetic properties of hard magnetic system Ce(Co1-xFex)4.4Cu0.6 (0 ≤ x ≤ 0.19)”. J. Alloys Compd., 883, 2021, 160866, doi:10.1016/j.jallcom.2021.160866.