News & Highlights

Research Highlight

Research Highlight

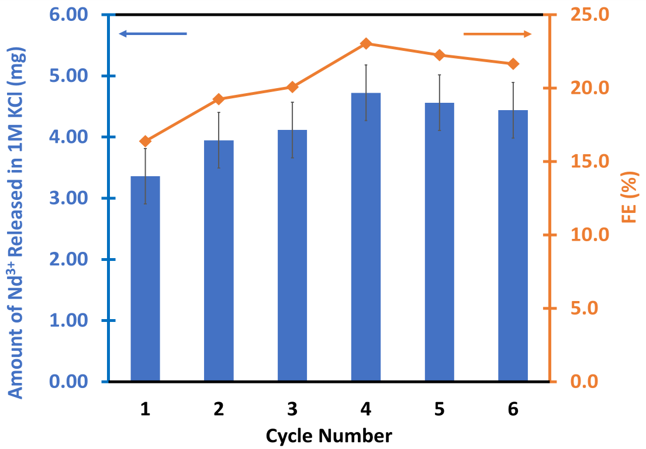

Pseudocapacitive separation of REE from dilute sources

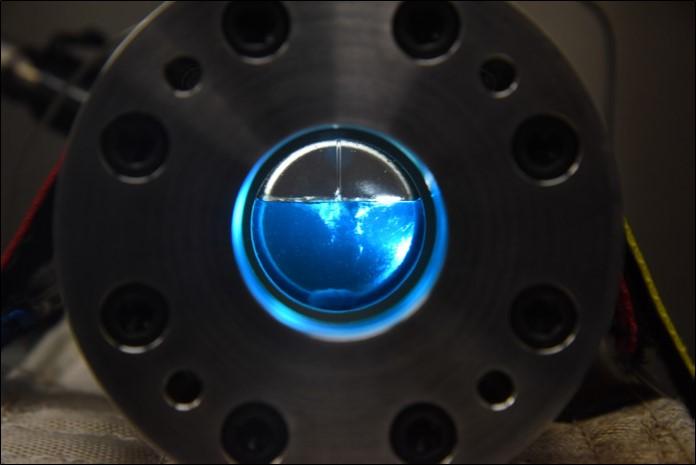

Efficient room-temperature neodymium electrodeposition in calcium-based electrolyte

Research Highlight

Research Highlight

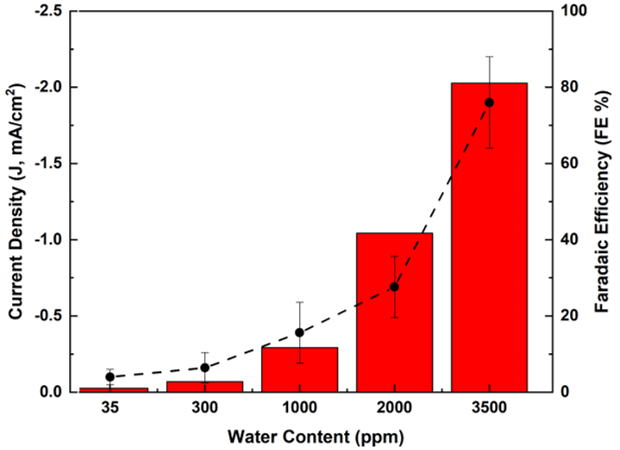

Water-additives on the electrochemical REM production in ionic liquid system

Research Highlight

Research Highlight

CMI technology RE-Metal wins 2021 R&D 100 Award

Two CMI technologies named 2021 R and D 100 Award winners

Luis Diaz Aldana at Idaho National Laboratory leads the CMI project "Low temperature REE metal production"

This project aims to develop a feasible pathway to achieve the metal production of rare earth elements (REE) through low temperature electro deposition in non-aqueous electrolytes. The activities of the project involve synthesis, characterization, and assessment of the electrolyte system as well as alternatives to deliver the REE to the electro-deposition cell through the use of REE feed anodes. Hence, the electro-deposition process has the dual purpose of showing that not only can metal ions be selectively plated onto the cathode affecting a separation, but also that the material phase can be changed from ionic to metallic; thus, effectively accomplishing electroplating and possible REE species separation.

CMI technology developed in this project area won an R&D 100 Award in 2021, as described in these news stories:

- Idaho National Laboratory wins four R&D 100 Awards

- Two CMI technologies named 2021 R&D 100 Award winners

CMI researchers working in this project include Abderrahman Atifi

CMI researchers at Idaho National Laboratory developed an award-winning RE-Metal Technology