CMI researchers from Lawrence Livermore National Laboratory conducted the activity for this highlight

Innovation

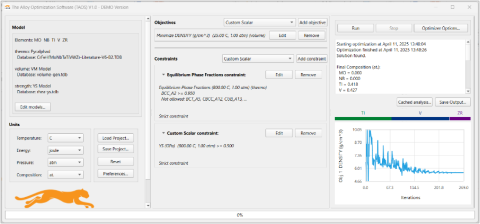

Software enabling alloys designed to meet targeted requirements.

Achievement

A user-friendly commercialized tool that enables computational design of optimal alloys with a targeted property (e.g., melting temperature) under constraints (e.g., density) in minutes to hours –vs- weeks for traditional modeling methods.

Significance and Impact

- Reduced cost and time to market for alloy designs.

- Can be run by non-specialists on stand-alone computers.

- Automates down-select from a large multicomponent phase space to a manageable number of experimental targets.

- Viable for both conventional and advanced manufacturing.