CMI researchers from Ames National Laboratory conducted the activity for this highlight

Innovation

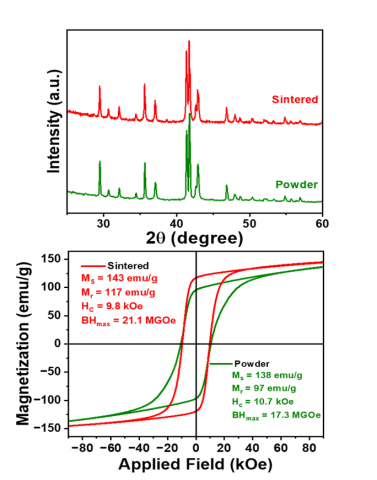

Direct conversion of Sm2O3 into Sm2Fe17 phase via reduction-diffusion (RD) produces Sm2Fe17N3 magnets with improved hard-magnetic properties.

Achievement

Developed a “bottom-up” CaO assisted RD approach to minimize the particle aggregation thereby enhancing the coercivity. RD at 950°C produced high-purity (98%) Sm2Fe17N3 powders, which when sintered resulted in a bulk magnet with (BH)max = 21.1 MGOe and 88% relative density.

Significance and Impact

- Criticality and cost: the material is mostly Fe (~74% wt.%) and non-critical rare earth, Sm, as well as earth-abundant nitrogen.

- When fully developed, single grain-single particle Sm2Fe17N3-based materials when sintered are expected to replace heavy rare earth Nd-based magnets in high performance, high temperature applications.

Hub Goal Addressed

Microstructural engineering to reduce the need for dysprosium.