This CMI research was conducted at Idaho National Laboratory with collaboration from the Colorado School of Mines highlight

Achievement

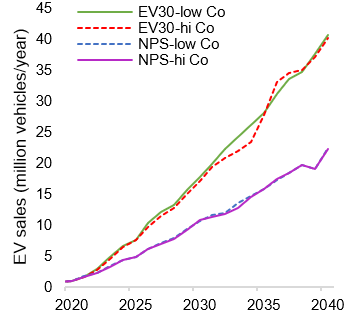

The supply chains of cobalt, copper and nickel were analyzed given various deployment scenarios of electric vehicles and battery chemistries.

Significance and impact

Electric vehicles will be an important part of a low-carbon economy, yet growth analysis accounting for both demand and supply of raw materials is lacking. This work considers market dynamics of primary and secondary production of Co, Cu and Ni to better constrain deployment projections.

Details and next steps

A system dynamics model was created to calculate raw materials production:

- Electric vehicle sales in high growth scenarios are similar between high and low Co content chemistries due to shifting from Co to Ni constraint starting in 2035 (Figure)

- Battery lifetime reductions from 8 to 5 years increases maintenance demand by 20-35%