CMI researchers from Ames National Laboratory conducted the activity for this highlight

Innovation

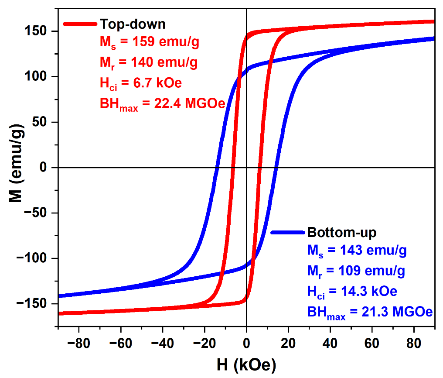

Two different approaches – bottom-up and top-down – were investigated to determine the optimal method for producing the SmFeN powders at scale.

Achievement

By optimizing the top-down procedure, scaled up Sm2Fe17N3 powder production to 12g, achieving a remarkably y high Ms = 159 emu/g and Mr = 140 emu/g, with BHmax = 22.4 MGOe.

Significance and Impact

- Criticality and cost: material is mostly Fe (~74% wt.%), containing non-critical rare earth Sm as well as earth-abundant N.

- Next step is to form fully dense Sm2Fe17N3-based materials, comprising single grains and particles that, are expected to rival Neo magnets in performance.

Hub Target Addressed

Accelerating discovery and deployment of new permanent magnets.