CMI researchers at Missouri S&T conducted the activity for this highlight

Innovation

Flowsheet development for the selective separation of platinum group metals (PGMs), precious metals, and critical elements from selenium (Se) sludge.

Achievement

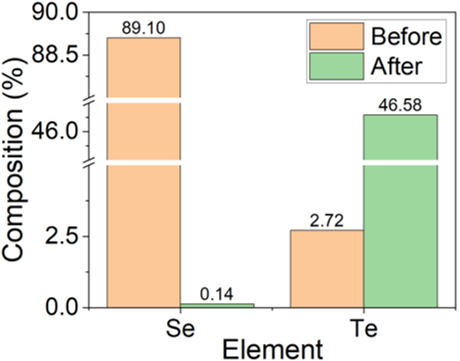

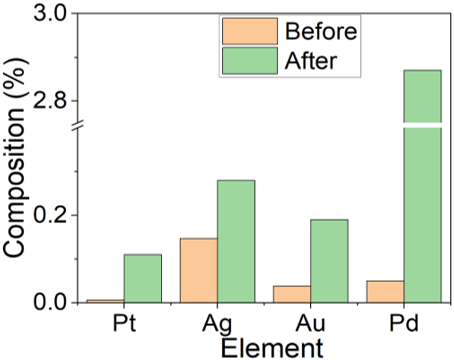

Missouri S&T team roasted crude Se sludge to remove Se, concentrate PGMs, and precious elements. Results show that ~99.9% Se can be selectively removed while keeping ~100% PGMs and tellurium (Te) in the roast residue. Concentration of PGMs and Te in the roast residue increased by at least 17-fold.

Significance and Impact

- Increase domestic production of PGMs.

- Decrease energy consumption.

- Supply chain diversification.

Hub Target Addressed

Improving the efficiency of PGM production from domestic sources.