CMI researchers from Ames National Laboratory and Idaho National Laboratory conducted the research for this highlight.

Achievement

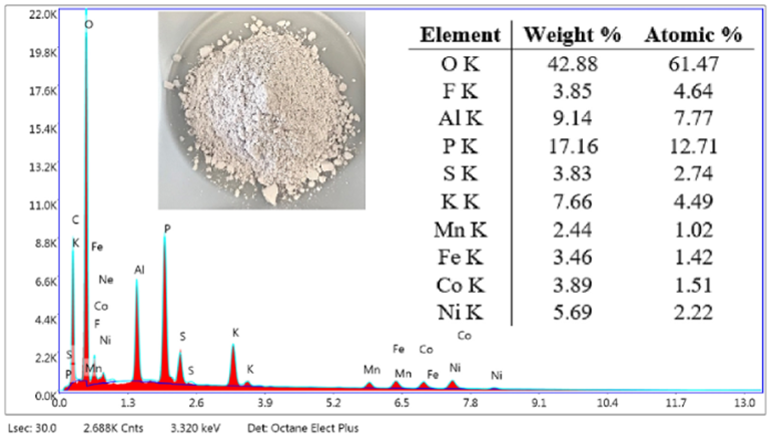

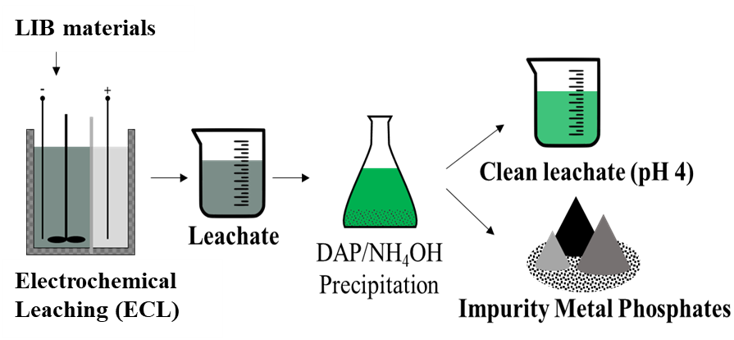

Efficient new approach for removal of impurity metals from lithium-ion battery leachates.

Significance

- Simple method to remove Al, Fe and Zn while minimizing critical elements losses.

- Coupled with EC-Leach, produces a solution ready for conventional separation by SX or IX.

Details and Impact

- Al and Fe are deleterious for separation and final product purity, and removal typically requires large pH swing and difficult removal of fine precipitates.

- New method operates at pH 4 and generates a coarse precipitate that is easy to separate.

Hub Target Addressed

Recovery and conversion of critical minerals into high value refined products.