CMI researchers at Oak Ridge National Laboratory and Ames Laboratory conducted the research for this highlight

Innovation

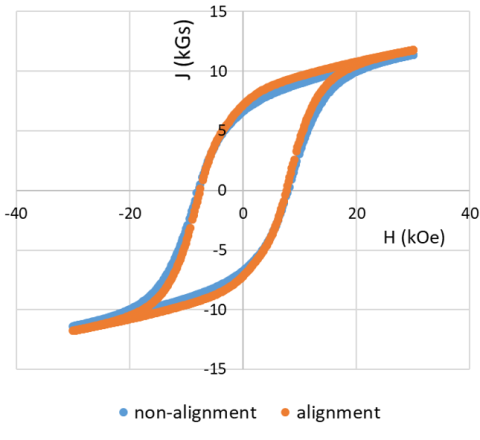

Hydrogenation-Disproportionation-Desorption-Recombination (HDDR) processed powders were produced with an applied field of 1 T during the hydrogenation-disproportionation (HD) step of the process

Achievement

- Samples showed only Nd2Fe14B in XRD (no oxide or α-Fe).

- Good coercivity despite unoptimized heat treatment parameters.

- Powders are mostly isotropic but there are signs of potential to induce anisotropy. Anisotropy can be further enhanced by controlling hydrogen pressure and magnetic field.

Significance and Impact

- Established a new process for producing HDDR powders.

- Bonded Nd-Fe-B is the primary type of Nd-Fe-B magnet produced in North America; hence, production of enhanced powders can enable the U.S. magnet industry.

Hub Target Addressed

Win industry adoption of three technologies related to materials substitution for rare earth magnet materials.