CMI researchers from Idaho National Laboratory conducted the activity for this highlight

Innovation

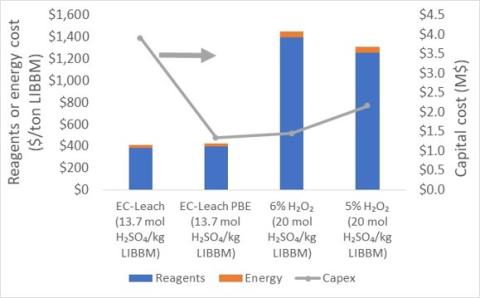

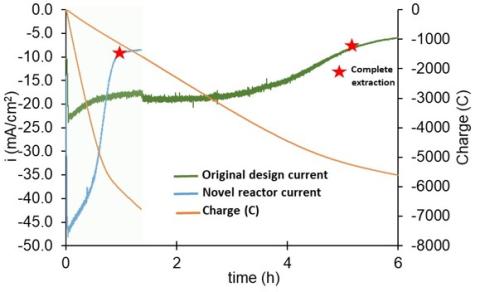

A combination of kinetic analysis, process modeling, and reactor re-engineering led to significantly faster leaching, decreasing EC-Leach capital costs to below traditional hydrometallurgical leaching.

Achievement

Redesign of the electrochemical cell for LIB metals extraction from black mass allowed an 85% reduction in processing time, drastically reducing capital costs while maintaining advantages in chemical and energy consumption. A model was developed to predict processing times and current profiles, enabling scale-up design.

Significance and Impact

- Advances commercialization potential for EC-Leach.

- Demonstrates novel configuration of slurry electrolysis that can be applied to processing of other solid substrates.

Hub Target Addressed

- Energy and material efficient hydrometallurgical processing.

- Minimizing hazardous chemical use and waste generation.