CMI researchers at the Florida Industrial & Phosphate Research Institute (FIPR Institute) conducted the activity for highlight.

Innovation

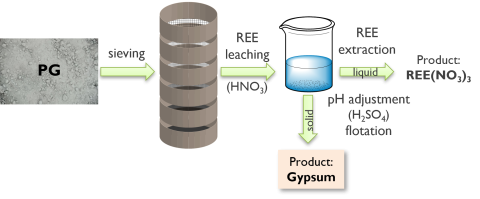

An alternative flotation process for phosphogypsum (PG) purification was developed that operates directly in acidic pulp, using sulfuric acid for pH control and an amine collector, eliminating alkali additions and thus reducing processing cost.

Achievement

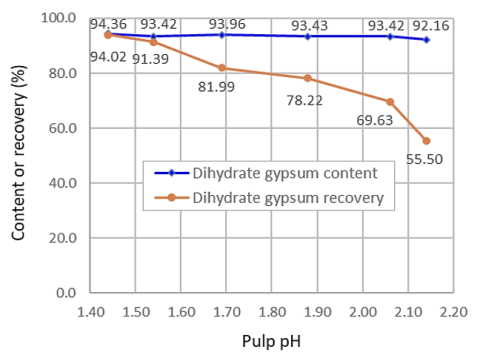

- At an optimized pulp pH of ~1.4, the flotation yielded a ~93% gypsum (CaSO₄·2H₂O) grade and up to 94% recovery.

- Once the solid product is separated, the sulfuric acid solution is recycled for subsequent pH control, minimizing reagent use.

Significance and Impact

Improving the economics of recovering REEs from accumulated PG while producing valuable products such as gypsum and cement.

Hub Target Addressed

Diversifying domestic REE supply chain and minimizing generation of hazardous waste.