CMI researchers at Ames National Laboratory conducted the research for this highlight

Innovation

Identified an effective method to improve the mechanical properties of Ce-Co-Fe-Cu gap magnet.

Achievement

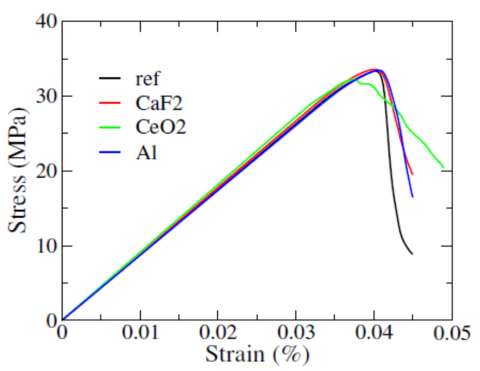

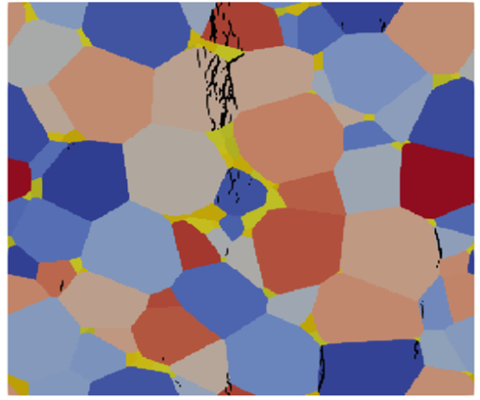

- Additives CaF2 and Al improve mechanical properties by arresting crack growth while CeO2 deflects crack path during propagation.

- The additives improve fracture strain by 3 – 8%, compared with a reference sample.

Significance and Impact

- Ce-Co-Fe-Cu is a potential “gap” magnet suitable for many applications including vehicle auxiliary motors.

- Improved mechanical properties will enhance reliability in service conditions.

- Tougher Ce-Co-Fe-Cu magnets will also reduce materials losses during manufacturing and post-manufacturing processing.

Hub Goal Addressed

Increase speed of discovery and integration.