CMI researchers from University of Arizona conducted the activity for this highlight

Innovation

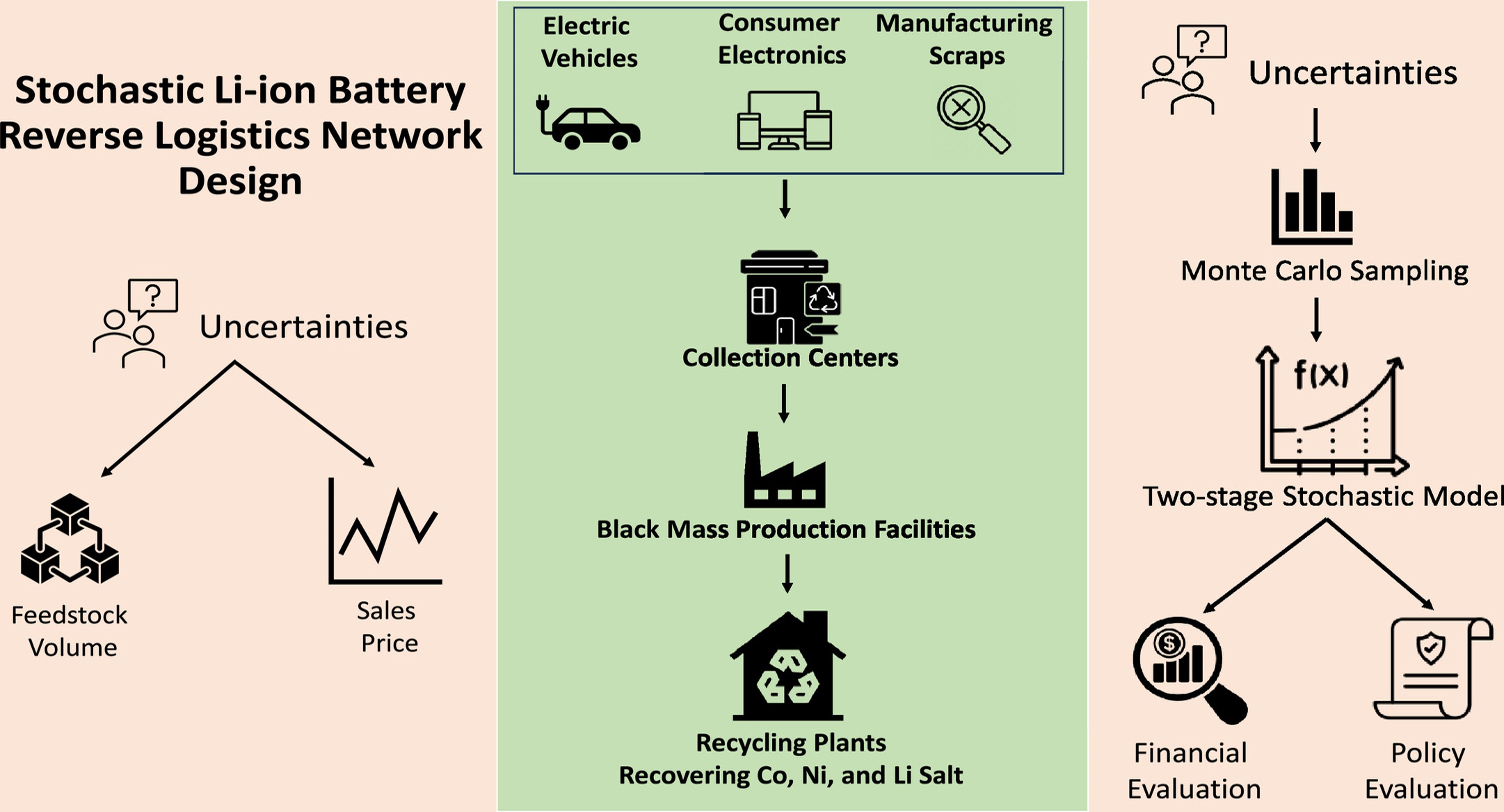

Used a two-stage stochastic optimization model, with the objective of maximizing profit in the United States, to optimize the reverse logistics network under price and feedstock volume uncertainties.

Significance and Impact

- Without government incentives, the recycling industry may expect $3.5 to $3.7 billion profit over the next 10 years by recycling 57% of the available feedstock.

- Mandating 90% spent battery collection would result in a negative profit and increased feedstock collection of 93%.

Hub Target Addressed

- Developing criticality assessments and supply chain analysis tools

- Assessing economic impacts