CMI researchers from Pacific Northwest National Laboratory conducted the activity for this highlight

Innovation

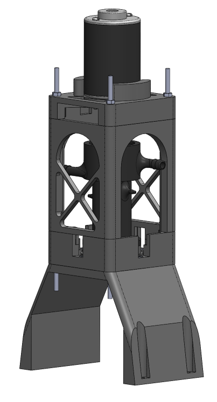

Designed 3D printable countercurrent centrifugal contactor customizable for critical mineral recovery using liquid-liquid extraction technology.

Achievement

Demonstrated proof-of-concept fabrication of 3D printed contactor prototype with REE extraction from acidic solution using DGA-based organic solvent.

Significance and Impact

3D printable contactors allow for rapid fabrication to evaluate material compatibility, including corrosive media; facilitate customization and promote scale-up through modularity. 3D printed contactors will accelerate flowsheet development for critical mineral recovery. 3D printable centrifugal contactor capability is currently being established at PNNL.

Hub Target Addressed

CMI trains the critical materials workforce of the future.