CMI researchers at Lawrence Livermore National Laboratory, University of Tennessee - Knoxville and Eck Industries conducted the research for this highlight

Innovation

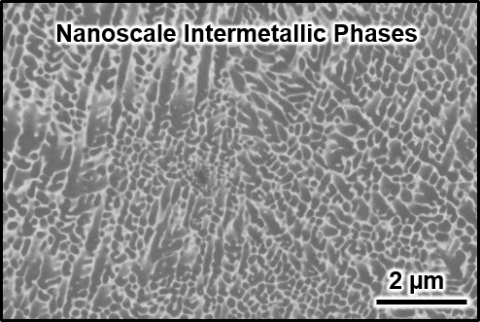

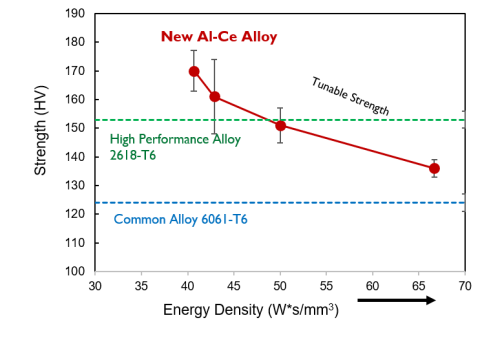

A novel Aluminum-Cerium alloy developed for 3D printing has exceptional strength that can be fine-tuned with process parameters.

Achievement

- Alloy strength can be controlled with 3D printing parameters alone, enabling local strength tuning within a part- something not possible with any current 3D printed or conventional alloy.

- The alloy is easily printable and has strength comparable to high performance commercial Al alloys.

Significance and Impact

Here we demonstrate how an alloy designed specifically for 3D printing can enable a new approach to part design. With this alloy, engineers can decide where strength is needed and not needed within a single part, making performance more customizable and reliable.

Hub Target Addressed

Diversify supply of REE by increasing demand for Ce in a high value product.