CMI researchers from Oak Ridge National Laboratory, National Energy Technology Laboratory and University of Houston-Downtown conducted the activity for this highlight

Innovation

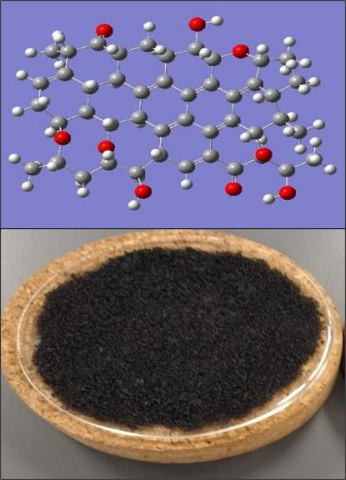

First computational study of the only known process for converting waste polyethylene into highly crystalline, battery-grade graphite.

Achievement

Undergraduates at the University of Houston–Downtown used computational modeling to analyze the changes occurring when polyethylene is converted to highly crystalline graphite. Model predictions were confirmed by comparing theoretical and experimental infrared spectra.

Significance and Impact

- This research opens doors for improving & optimizing the chemical process.

- Future work will focus on predicting optimal process temperatures and analyzing subsequent process steps.

Hub Target Addressed

- Recovering critical materials from unconventional sources

- Training the critical materials workforce of the future.