CMI researchers at Idaho National Laboratory conducted the research for this highlight

Innovation

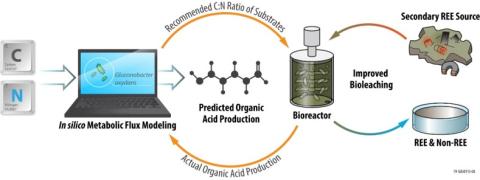

Developed a metabolic model for sugar conversion to chelating organic acids in Gluconobacter oxydans; the acids can be used for bioleaching of metals from solid wastes.

Achievement

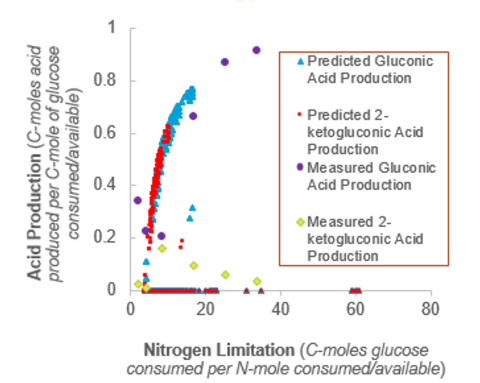

Modeling predicted increasing the C:N ratio in the feed to >10, gluconic acid production would increase substantially. This predictions was validated. When the C:N ratio was increased from 8 to 17, the gluconic acid production increased from 23 to 147 mM. Previous work has shown that higher gluconic acid concentrations are correlated with higher REE recovery yields from FCC catalyst.

Significance and Impact

Model predictions for bioconversion of glucose to organic acids can aid optimization of bioleaching yields, economics and environmental outcomes.

Hub Target Addressed

Advancing environmentally friendly and efficient recovery of critical materials from end‐of‐life products or wastes.