CMI researchers from Ames National Laboratory and Lawrence Berkeley National Laboratory conducted the activity for this highlight

Innovation

Mechanochemical processing facilitates the extraction of Li from domestic claystones – the nation’s largest Li resource.

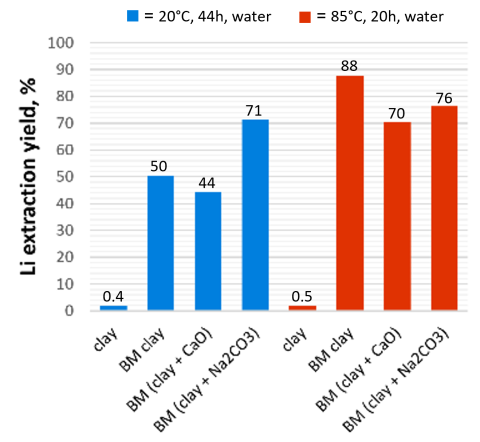

Achievement Mechanochemical activation of Li-bearing claystone eliminates the need for acid leaching, enabling efficient Li extraction using cold- or hot-water leaching resulting in up to 90% Li yield.

Significance and Impact

- The process results in a cleaner and more targeted extraction by eliminating the acid that is needlessly consumed dissolving calcium carbonate in clay, which does not contain lithium.

- Calcium carbonate is instead used as an intrinsic lithium leach promoter. Its milled products assist lithium release from the milled clay.

Hub Target Addressed

Recovery or purification processes to expand U.S. lithium production.