CMI researchers at Idaho National Laboratory conducted the activity for this highlight

Innovation

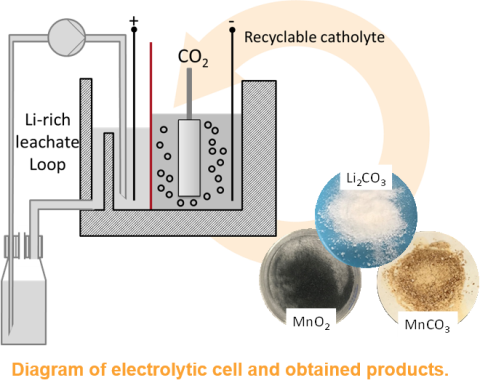

Separation and recovery of battery-grade Li2CO3 from lithium-ion battery (LIB) leachate using an electrodialysis process

Achievements

- High purity Li2CO3 and MnCO3 obtained through electrochemical separation after removal of Ni and Co from LIB leachate

- Membrane and catholyte can be re-used multiple times without affecting Li2CO3 purity; multiple stages improve purity.

- Energy requirement: 0.5 kWh/g Li

Significance and Impact

- Combination of carbon capture and utilization for mineral production

- Carbon-negative: CO2, the only chemical required, is solidified

- Generation of high purity Li2CO3 (>99.6%, metal basis)

- Application extendable to high purity LiOH production

Hub Targets Addressed

- Recovery and conversion into high value end products

- Highly selective separation from complex sources

Patent application