This CMI research was conducted at Ames Laboratory.

Achievement:

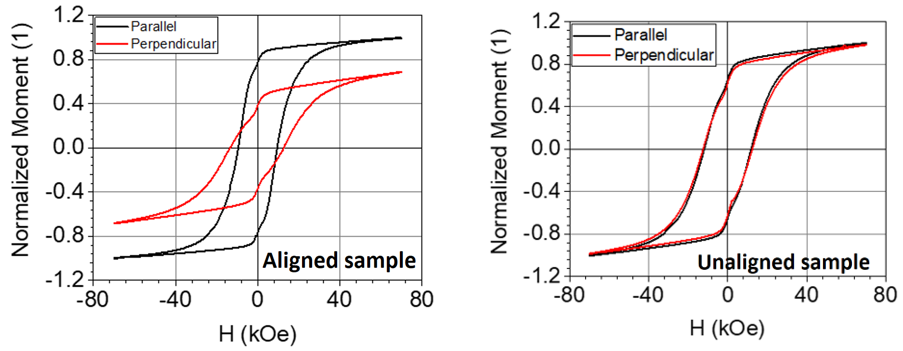

Demonstrated ability to perform in-situ alignment of magnetic materials in polymer-based bonded magnets during 3D printing

Significance and impact:

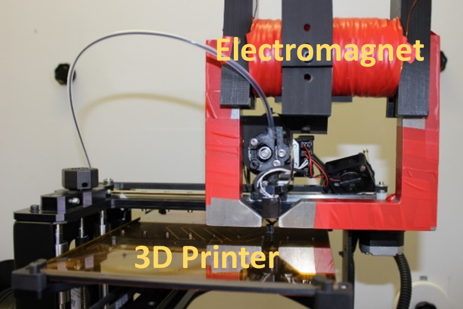

- Applies intense magnetic field during 3D printing which results in alignment of magnet particles

- Designed as an integrated attachment to existing 3D additive manufacturing printers and controlled through the printer’s motor and position controls

- Electromagnetic field source enables control of magnetic field via current control during 3D printing

- Eliminates risk of thermal demagnetization if permanent magnets were used to provide the in-situ field

Details and Next Steps:

- Increase loading fraction of magnet powder and, thus, better performing bonded magnets

- Extend to other magnet materials (e.g., Nd-Fe-B)

Additively printed bonded magnet performance enhancement with in-situ magnetic alignment